Videos

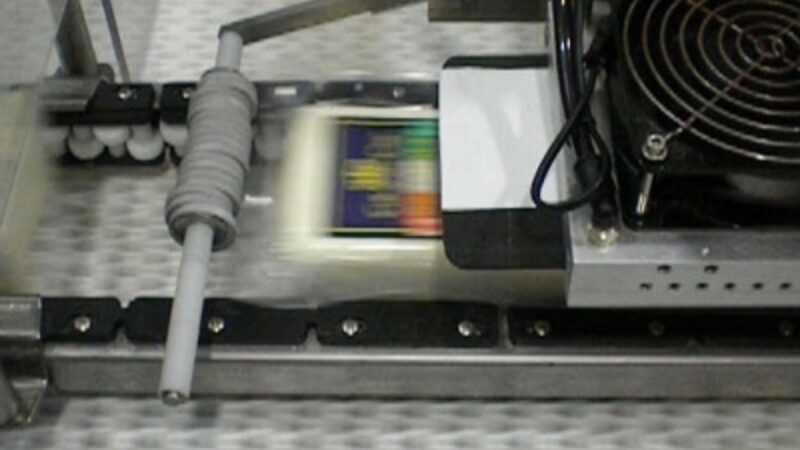

Logistics & e-commerce

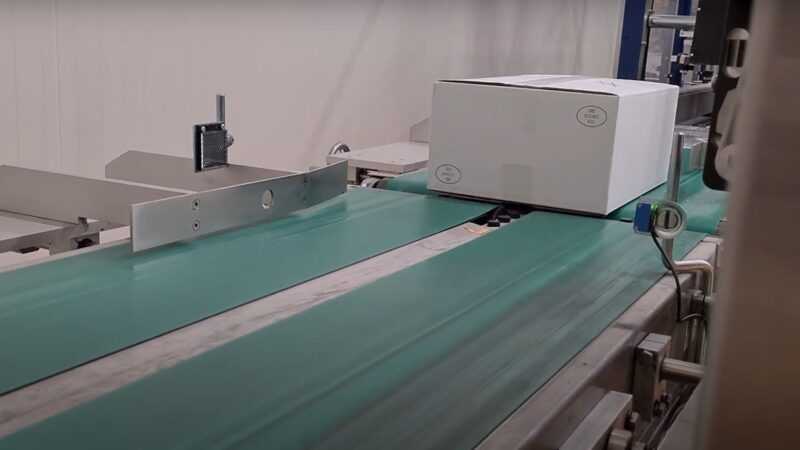

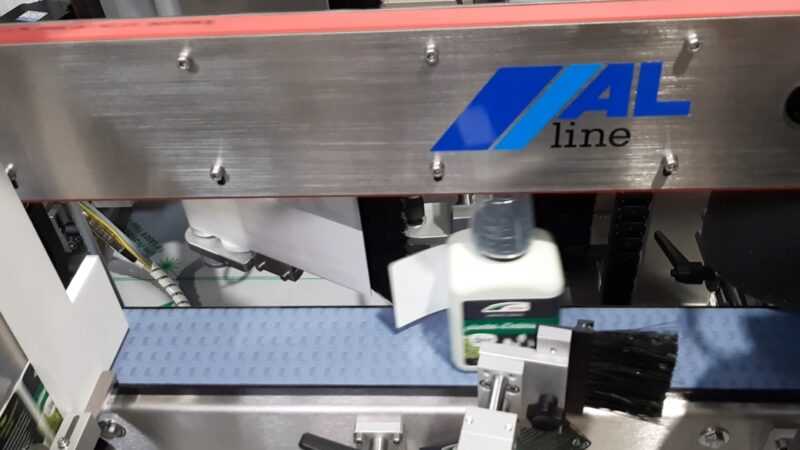

Top labelling packages with different heights

In the distribution centre of Johnson & Johnson, Codipack installed an print & apply system: an Evolabel eTamp.

Top label packages different heights

In e-commerce, time is money. And data must also be applied correctly. The shipping information on the shipping labels arrives flawlessly on the boxes at Ebay.

Top labelling of packaging

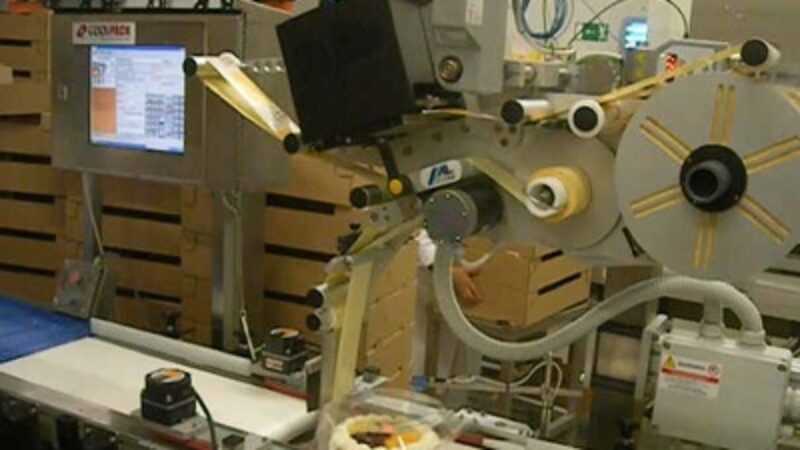

At our customer Trendy Foods, the Evolabel print & apply system automatically applies a label to the carton. Data is printed in real time.

Top labelling of parcels of different heights

This video is at our well-known customer Zalando. The shipping labels are printed at high speed and automatically applied on the boxes.

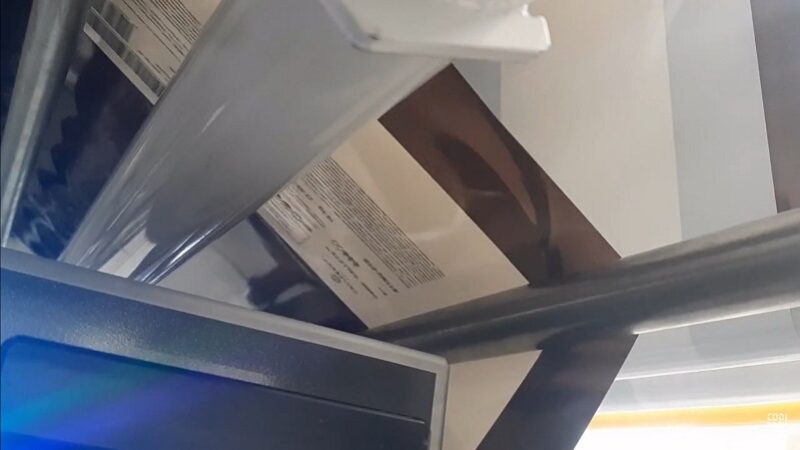

Codes on the side of cardboard boxes

In the logistics sector, it is important to be able to trace everything properly. Applying codes on packaging and boxes can be done efficiently with high resolution inkjet systems.

Labelling boxes of different heights

Codipack Group is more than a supplier of systems. We have technicians in house who install and thoroughly test everything.Dairy

Labelling the top of cheese packaging

Evolabel systems are reliable, safe and efficient. Here, the packaging of cheese is automatically labelled in a fast manner.

Codes on plastic bags

With this inline printer from Codipack, Friesland Campina applies text and codes to transparant plastic bags.

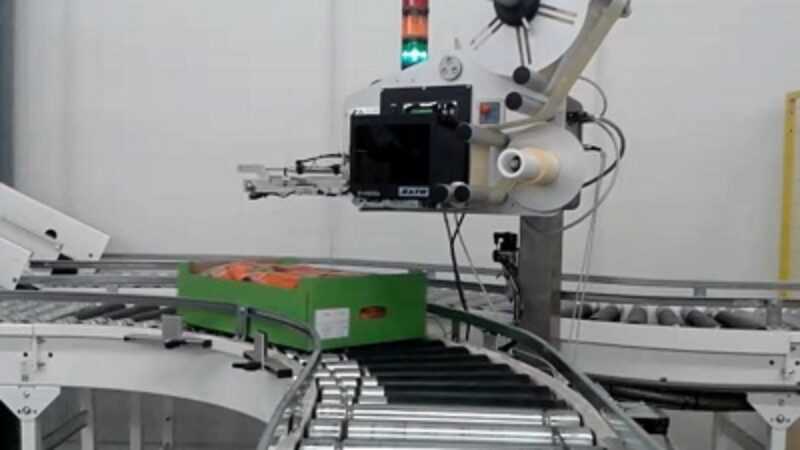

Labelling cardboard trays

Trays with butter are labelled here with a pneumatic tamp. Our customer Vandemoortele is focusing on automation and optimising its production.

Labelling the side of boxes

The expiry date, lot codes and other legal markings are applied to the packaging boxes at Kaasbrik.

Labelling the side of boxes

This chocolate dessert from Alpro is an instant hit. Each package is given a barcode.

Side labeling milk carton

At Alpro, the boxes of soy milk are labelled. This happens while they are in motion with a pneumatic tamp. This is an applicator that is driven by compressed air.Meat, fish and poultry

Top labelling pâté

This pâté is automatically labelled with ALtech's labeling machines. The pre-printed labels are applied quickly and efficiently.

Top coding of meat packaging

At Quality Meat Product, the plastic meat packaging is given a code on the top. This small character inkjet does this without contact.

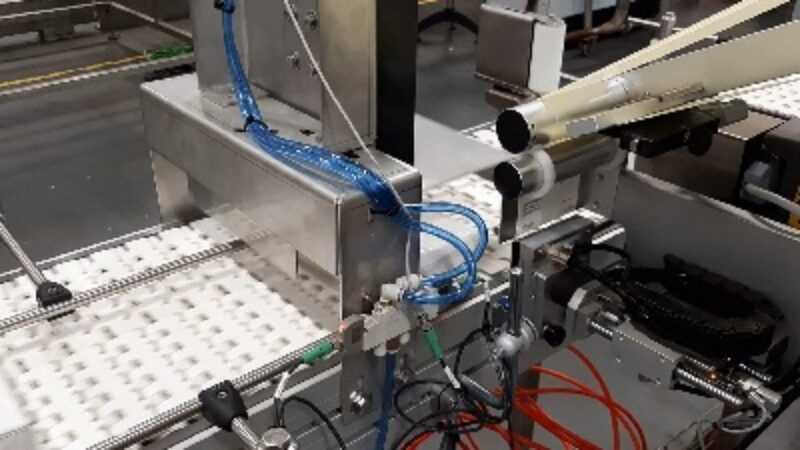

C-labeling menu

Revi Food is a producer of fish meals, located in the heart of the Ostend fish market. This print & apply system applies C-labelling to the fish meals.

C-labelling on packaging

Here you can see how we apply a C-label to a food package. This is an internal test at Codipack before we install the Evolabel system at our customer.

Codes and markings on boxes

This high resolution printer prints the cardboard boxes at Klaasen & Co in Ravels. In this way, the chickens in the soup are given the correct details so that they are always traceable afterwards.

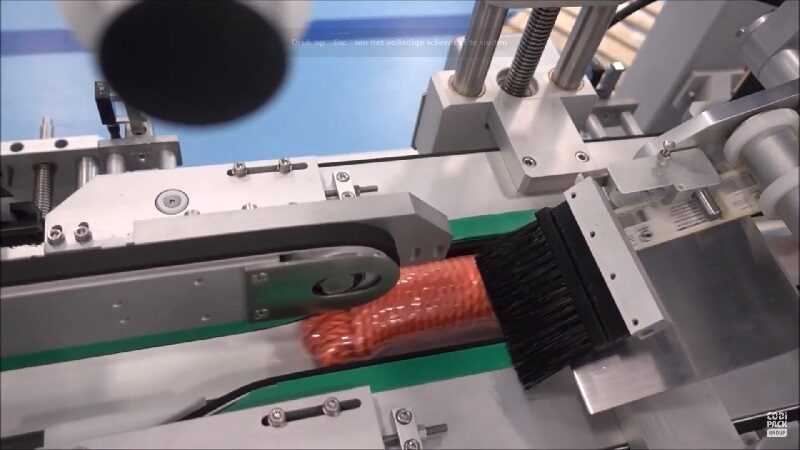

Wrap around labelling of meat sausages

Meat sausages are labelled with the systems of ALtech. This installation was done by Codipack Group at its customer.Fruit & vegetables

Top labelling of vegetables in tray

The Evolabel blow applicator automatically blows the labels onto the broccoli. This way, the vegetables are not damaged and everything runs smoothly.

Labelling the front and side of the box

These boxes of frozen vegetables get 2 separate labels in motion (!). These are applied with an Evolabel system on the front and side.

Labelling the front and side of frozen vegetables pallets

At Agifreez, a food manufacturer of frozen vegetables, we label the front and side of the pallets.

Labeling the front of box vegetables

The carrots here get a label on the front of the box. Everything goes quickly and efficiently with ALtech's systems. In this case an ALcode with AC04.

Labeling the side of trays of kiwis

The cardboard trays of kiwis of Zespri are automatically labelled. For this Codipack Group recommended a print & apply system of Evolabel.

Labelling the sides of pallets

At Zespri, the kiwis are labelled on pallets. Good for the traceability. Codipack ensures that these reach you correctly and well. The labels on the pallets are automatically applied with the systems of Codipack.Chocolate

Coding the top of packaging

On the packaging of Godiva Chocolade, we encode the lot codes and tht codes. This is done at high speed with a small character inkjet.

Labels on tin boxes

At our customer A&A Chocolaterie, the boxes are given a sleeve and a label is stuck at the bottom of the box. All ingredients and necessary markings and codes are listed on this.

Text and codes on packaging

At Callebaut, this built-in printer works continuously. Both texts and codes are printed on the plastic packaging in which the chocolate will be packed.

Labelling the side of boxes

This chocolate dessert from Alpro is an instant hit. Each package is given a barcode.Egg industry

Coding of eggs

These eggs get a code. This small character inkjet is integrated within a Moba system.

Top coding egg cartons

A high resolution inkjet printer codes the egg boxes at Dijverhof Ei. This is used, among other things, to indicate the best-before date.Animal food

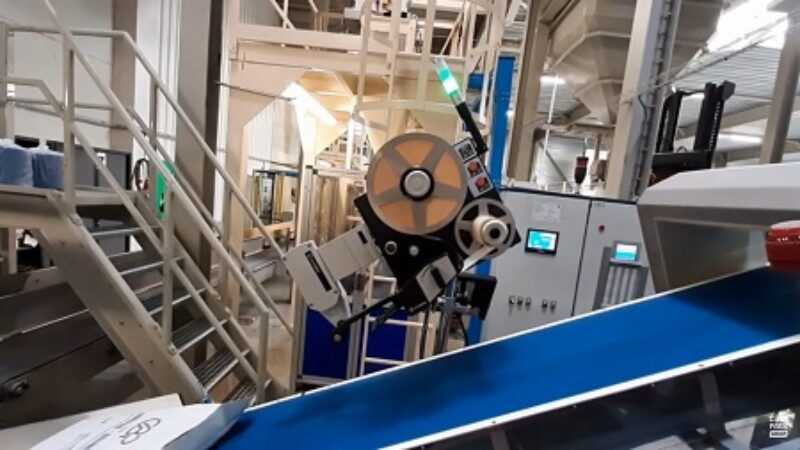

Top labeling feed bags

For years, the Dumoulin Group has been producing top-quality cattle feed. On these bags, all details are marked with the ALtech Alcode system.

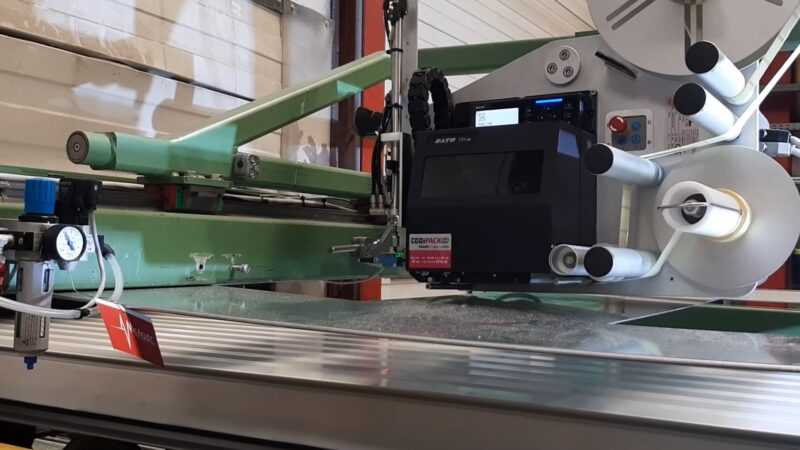

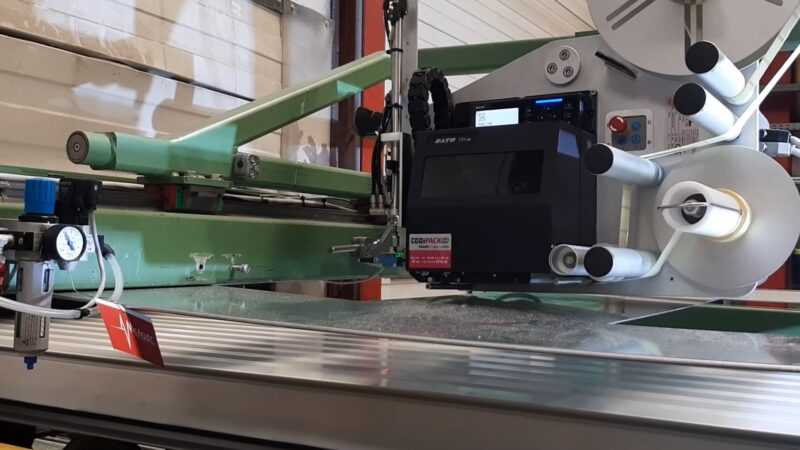

Labelling feeding bags

Trouw Nutrition has a wide range of animal feed. After labelling the bags, the 'verifier' quickly and carefully checks all the printed information.

Labelling dog treats on the side

How to label dog treats. Quickly and efficiently with ALtech's systems.Other food products

Top labelling on pockets

Aveve is betting on its own brand. On these empty bags a label is applied in an automatic way. Codipack Group took care of the installation.

Top labelling of packaging

At our customer Trendy Foods, the Evolabel print & apply system automatically applies a label to the carton. Data is printed in real time.

Top label packaging menu

On these Royal Foods menus, each portion is labelled with the ingredients and a best-before date using a pneumatically driven system.

Top labelling of food packaging

Here you see the Tamp applicator of Evolabel at work. This is an efficient and fast print & apply system offered by Codipack.

Top labelling of linseed bags

Labels with best-before dates, barcodes and ingredients are easily applied with Evolabel's eWipe at this family company specialising in cleaning linseed for human consumption.Coffee

Expiration date and lot code on coffee packaging

Codipack Group has installed a laser system at Rombouts. Our customer uses this system to apply permanent codes to packaging.

Side labeling package

At Colruyt, the ALtech ALritma automatically applies labels and the Allen Coding Hot Foil applies the date to the pre-printed label.

Labelling the top of a tin can

Here we automatically apply labels with promotions to the boxes at our customer Rombouts.Beverages & breweries

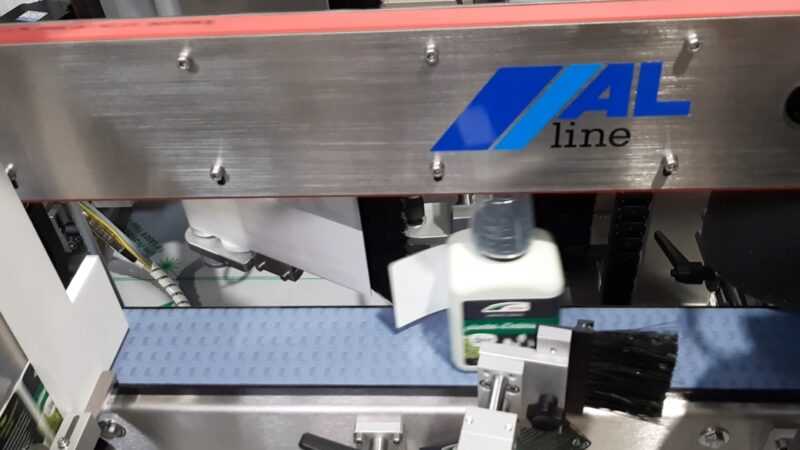

Labelling of sealed PET bottles

PET bottles are labelled by a large soft drink manufacturer. Here Codipack recommended the systems of ALtech.

Glass bottle of beverage labelled in 3 places

In the beverage industry, a lot of attention is paid to the label. Often, labels are provided in different places. Here you can see how bottles are labelled in 3 places simultaneously.

Wrap around labeling of glass bottles

A wrap around label on a glass bottle. It is not a senicure. But with ALtech's systems, it is. Here you can see them at work in the food sector. These machines are also often used in the beverage sector.

Lasering of soft drinks

At this soft drink giant, the codes are applied at extremely high speed. The laser systems are reliable and the process runs at very high speed.

Side labelling cardboard trays soft drinks

The Evolabel systems are often used in the beverage industry. Cardboard boxes are labelled at high speed with a pneumatically driven system.

Side labelling of beer crates

Codipack is very active in breweries. Both small and larger. Here you see a pallet labeler which provides the crates of beer with SSCC labels.Chemical industry

Codes on empty plastic packaging

Compo Expert produces fertilisers for professional users in the fruit and vegetable sector.

Wrap around labelling of plastic bottles

Wrap around labelling of plastic bottles in an automatic way. Some ALtech systems are specially designed for this.

Coding of plastic bags

Borealis produces large quantities. Speed is also important. Here, filled bags are coded at high speed with an inkjet HP.

Wrap around labeling of a can

DCM supports every hobby gardener and professional gardener with qualitative solutions. For the labelling of their fertilisers they rely on Codipack.

Wrap around labelling of aerosol cans

These aerosols are labelled all around. This happens in a fully automatic way with the systems of Codipack.Construction materials

Print on top side of metal profiles

Avasco Industries specialises in the production of metal storage systems. Here, profiles are coded with a small character inkjet.

Coding the top of PVC pipes

Here, a marking is applied to the top of PVC pipes. This application is often used in the construction sector.

Labeling top of concrete bags

Automatically labelling filled bags with the systems of ALtech. Codipack installed this system for its customer Cugla, a company that supplies products for the concrete mortar industry.

Labelling cement bags

Also in dusty environments Codipack systems do their job. Here we see a print & apply system labelling cement bags.

Coding on narrow cables

At Caparis, the cables are printed with text and codes. This is done with a small character inkjet printer, the Jet3up from the brand Leibinger.

Apply codes on side of concrete block

With the DOD 2.0 print heads we apply markings on concrete blocks at Holcim Belgium. They are from the brand Rea Jet that Codipack distributes.Wood-processing industry

Coding on plates, crates and pallets

Here you can see various applications on wood, including laser systems and inkjet for permanent coding. Print & apply is also possible.

Bottom labelling of wooden planks

Labelling wooden boards efficiently and at high speed, that is what you do with Codipack. Here you see the eWipe system of Evolabel at work.

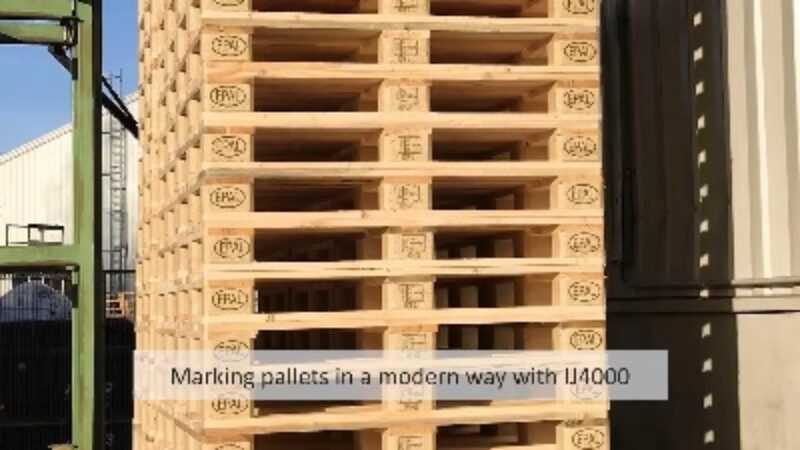

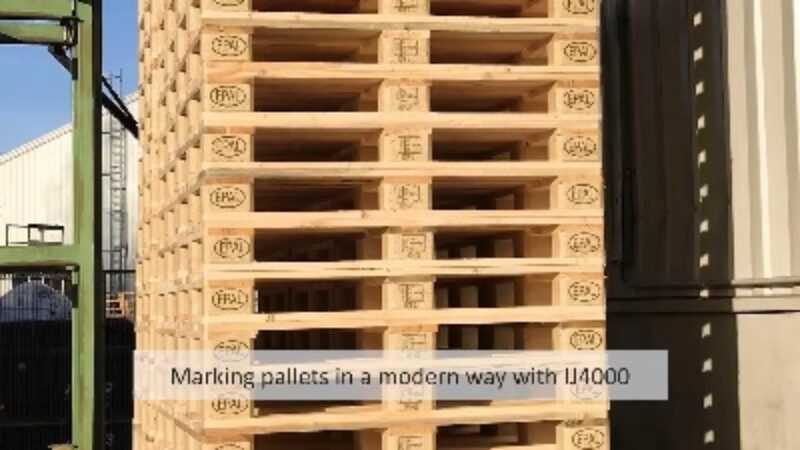

Printing on pallets with inkjet

The European Pallet Association (EPAL) has approved an inkjet system from Codipack for printing on pallets. Discover the Diagraph IJ4000.

Printing on the side of large package with plastic foil

This high resolution inkjet from Codipack can also apply logos and text clearly in colour.

Marking the side of a wooden pallet

Pallets in the wood processing industry are often marked. This can be done easily with the DOD system from Rea Jet.

Coding the side of pallets

This high resolution inkjet is often used in the wood processing industry. Here, the system applies codes to pallets.Automotive & electronics

Marking around car tyres

A clear marking, around car tyres. This high resolution inkjet system from Rea Jet shows how it can be done..

Top labelling of car tyres

Everything gets a label or a code. So do packaged car tyres. Here you can see how these car tyres are automatically labelled with the ALtech system ALcode.Textile sector

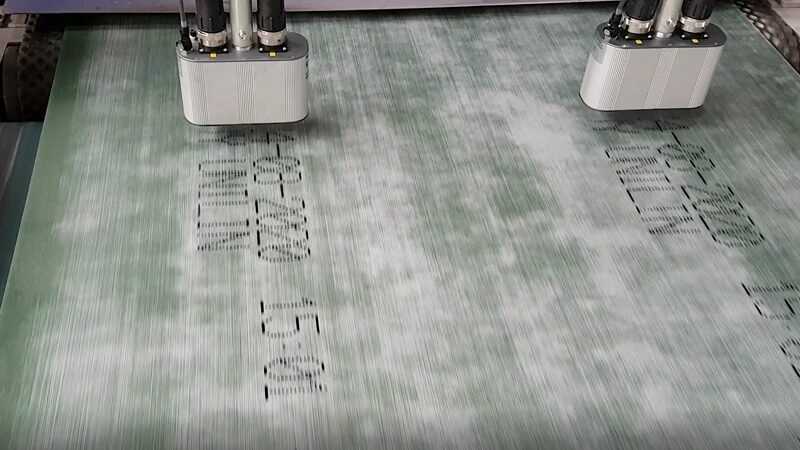

Top coding patterns

For this textile manufacturer of curtains, the patterns are drawn with an inkjet. This makes it possible to work very precisely.

Top labelling of textile

Textiles can also be labelled perfectly. With a Tamp applicator, for example. And the right labels with the right glue. Ask your specialist at Codipack for more information.

Labelling boxes of different heights

Codipack Group is more than a supplier of systems. We have technicians in house who install and thoroughly test everything.

Lasering of the sides of packaging boxes with textile

The cardboard packaging of this textile manufacturer is lasered on the side. The codes are permanent.Metallurgical industry

Top labeling of steel

At ArcelorMittal they produce innovative and sustainable steel products. These are given a label that is printed in real time and then applied.

Wrap around coding of metal barrel

Codes are placed on these barrels. This is done with a Rea Jet DOD print head. While the barrels are rotating, the inkjet is 'sprayed' onto them.Packaging, paper & cardboard

Pallet labeler with motorized stand

For the large paper manufacturer SCA, Codipack has installed several pallet labellers. These have a 'motorised stand'. So you label your pallet at the place that you want.

Pallet labeller with motorised stand

For the large paper manufacturer SCA, Codipack has installed several pallet labellers. These have a 'motorised stand'. So you label your pallet at the place that you want.

Top labelling packaging

At SCA - one of the largest paper manufacturers in Europe - Codipack automatically applies labels to the packaging material.

Front pallet labelling with SSCC labels

At our customer Moderna Products we have installed the Evolabel pallet labeler. This labels one side of the pallets automatically.Cosmetics & pharmaceuticals

Top labelling packages with different heights

In the distribution centre of Johnson & Johnson, Codipack installed an print & apply system: an Evolabel eTamp.

Printing codes on blisters

The codes on medication must be very clearly legible. Large volumes are produced at high speed with this inkjet HP.

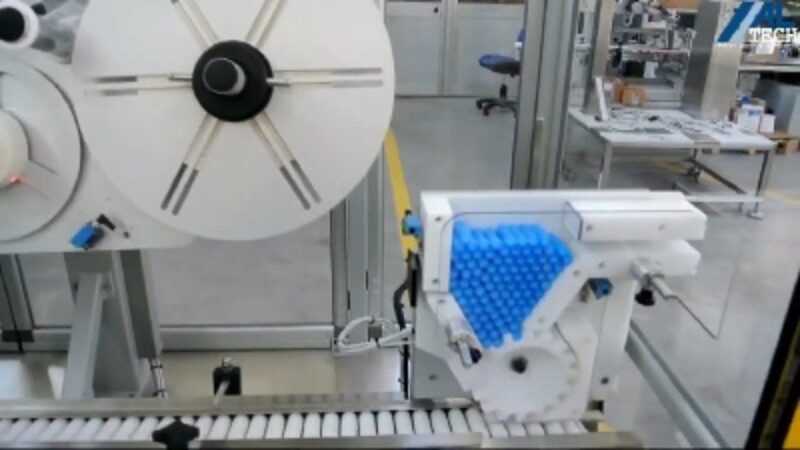

Wrap around labelling of vials

This labelling machine has been specially designed for labelling vials and boxes in the pharmaceutical industry.

Printing on bottom of glass bottles

The bottoms of these glass bottles are coded at high speed in the pharma sector. This is done with pigment ink for greater contrast with a small character inkjet.

Labelling the bottom of glass bottles

At Estee Lauder, each make-up bottle is labelled at the bottom. This happens automatically and at high speed.

Wrap around labeling of plastic and glass bottles

With this system you can label semi-automatically self-adhesive labels on cylindrical products. For this Codipack has the ALtech ALmatic in its range.Tobacco

Wrap around labeling of tubes

Tubes and vials are often labelled all around (wrap around labeling). Like here, where these tubes are automatically labelled. This is done at high speed.

Wrap around labeling of tubes of cigars

These tubes in the tobacco sector are labelled and coded. Everything happens fully automatically with the ALtech ALline and ALritma at our customer Cortes.

Lasering of top and side of wooden boxes

At this cigar manufacturer, we laser the wooden boxes. You can decide what will be applied on them.Horticulture

Applying plant passports on pots

A plant passport is mandatory within the EU. You can apply this with a small character inkjet printer. Do you have dark pots? Then this can be done with pigmented or soft pigmented ink.

Wrap around labeling of a can

DCM supports every hobby gardener and professional gardener with qualitative solutions. For the labelling of their fertilisers they rely on Codipack.

Side coding of boxes with high resolution inkjet

These cardboard boxes at Bio Nova are given the necessary codes. This is done with Diagraph's high resolution printer.

Labelling the side of plant trays

Here the plant passport is applied with the systems of ALtech at a Codipack customer.

Coding the side of bags of fertiliser

Filled bags are coded here with the Leibinger JET2neo. This small character inkjet can work at high speed.

Automatic labelling of a bouquet of flowers

These flowers are automatically labelled. This is carefully applied to the foil of the flowers, so that they are not damaged.Corporate videos

Evolabel corporate video

Evolabel is a premium partner of Codipack Group. Evolabel stands for simplicity and reliability. Its print & apply systems are compact and safe to use.

Altech corporate video

ALtech supplies labelling lines and automatic labelling systems. ALtech also has special machines for wrap around labelling.

Leibinger corporate video

With Leibinger you can count on genuine German quality. Every component of every inkjet printer is thoroughly checked to ensure it is worthy of the Leibinger name.

NiceLabel corporate video

NiceLabel is a leading developer of label software to design, print and manage labels. Ideal to digitally transform your entire labelling process.

Macsa corporate video

Macsa's laser systems code at very high speeds in various sectors. The FMCG market often uses them.

Rea Jet corporate video

Rea Jet's inkjet systems are ideal for large character marking, for example, on wood or in high resolution on various materials.Pallet labeler Evolabel

Labelling of single and stacked pallets

Here you can see the print & apply system at Scott Automation for both single pallets and 2 pallets on top of each other.

Pallet labeler with motorized stand

For the large paper manufacturer SCA, Codipack has installed several pallet labellers. These have a 'motorised stand'. So you label your pallet at the place that you want.

Pallet labeller with motorised stand

For the large paper manufacturer SCA, Codipack has installed several pallet labellers. These have a 'motorised stand'. So you label your pallet at the place that you want.

Pallet labeling – general video

In this video you can see the Evolabel pallet labeller at work in various sectors.

Front and side pallet chips labelling with ‘verifier’

Roger Roger distributes and exports chips. At this customer, Codipack systems label the pallets. This is equipped with a 'verifier' so that the slightest error is detected.

Labelling the front and side of frozen vegetables pallets

At Agifreez, a food manufacturer of frozen vegetables, we label the front and side of the pallets.Pallet labeler ALtech

Labelling of wooden pallet with stapler

At this customer, who is active in building materials, you can clearly see that the wooden pallets are automatically labelled.

Front and side labelling pallet

ALtech's ALcode P ensures that the correct data is put on your pallets. This is an example from a customer in the chemical industry.

Side labelling of beer crates

Codipack is very active in breweries. Both small and larger. Here you see a pallet labeler which provides the crates of beer with SSCC labels.

Labelling the sides of pallets

This pallet labeller prints A5 SSCC labels and applies them to one or more sides of a pallet.

Labelling the side of pallets

Here you see the pallet labeling systems of Codipack at work at Vandersanden. This pallet labeller is from the brand ALtech.

Labelling 4 sides of pallet

Would you like to label not 3 but 4 sides of a pallet? That is also possible. Here you can see how we do it with the ALtech labelling system.Print & apply Evolabel

Top labelling of vegetables in tray

The Evolabel blow applicator automatically blows the labels onto the broccoli. This way, the vegetables are not damaged and everything runs smoothly.

Top labelling packages with different heights

In the distribution centre of Johnson & Johnson, Codipack installed an print & apply system: an Evolabel eTamp.

Top label packages different heights

In e-commerce, time is money. And data must also be applied correctly. The shipping information on the shipping labels arrives flawlessly on the boxes at Ebay.

Top labelling of packaging

At our customer Trendy Foods, the Evolabel print & apply system automatically applies a label to the carton. Data is printed in real time.

Top label packaging menu

On these Royal Foods menus, each portion is labelled with the ingredients and a best-before date using a pneumatically driven system.

Top labelling of food packaging

Here you see the Tamp applicator of Evolabel at work. This is an efficient and fast print & apply system offered by Codipack.Print & apply ALtech

Top labelling on pockets

Aveve is betting on its own brand. On these empty bags a label is applied in an automatic way. Codipack Group took care of the installation.

Top labeling of steel

At ArcelorMittal they produce innovative and sustainable steel products. These are given a label that is printed in real time and then applied.

Top labelling of textile

Textiles can also be labelled perfectly. With a Tamp applicator, for example. And the right labels with the right glue. Ask your specialist at Codipack for more information.

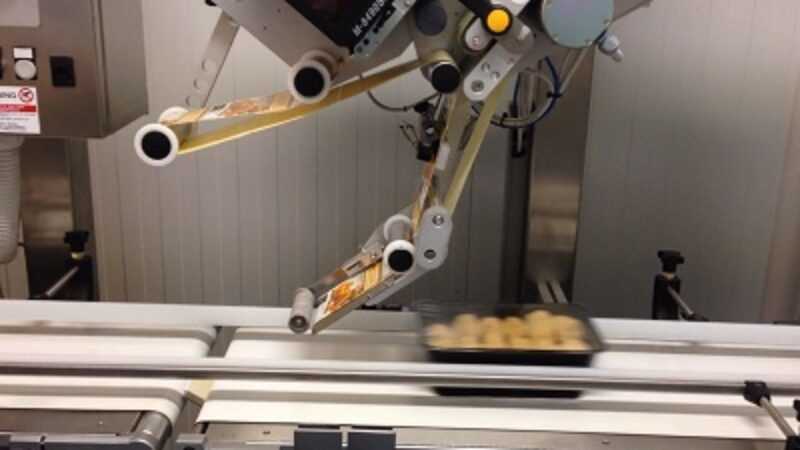

Labelling the top of packaging croquettes

The top and bottom of these packaged foods are labelled together. Codipack Group took care of the installation of this system.

Top labeling of pack of herbs

These herbs get a label at our customer Vitacress. Codipack Group installs the machine and adjusts it to your needs.

Top labeling feed bags

For years, the Dumoulin Group has been producing top-quality cattle feed. On these bags, all details are marked with the ALtech Alcode system.Labeling systems

Top labelling pâté

This pâté is automatically labelled with ALtech's labeling machines. The pre-printed labels are applied quickly and efficiently.

Labelling of sealed PET bottles

PET bottles are labelled by a large soft drink manufacturer. Here Codipack recommended the systems of ALtech.

Wrap around labeling of plastic and glass bottles

With this system you can label semi-automatically self-adhesive labels on cylindrical products. For this Codipack has the ALtech ALmatic in its range.

Labeling bottles of javel on the side

Labelling of javel cans at our customer Loda. This is done accurately with the systems from ALtech.

Labelling dog treats on the side

How to label dog treats. Quickly and efficiently with ALtech's systems.

Side labelling shipping boxes

Various systems are in use at Nedcargo whereby the shipping label is automatically applied to the shipping package.Label conveyor

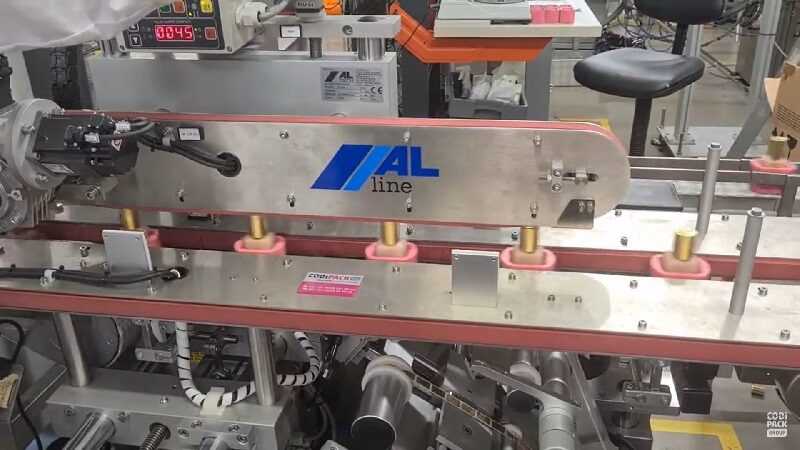

Top labelling of products

Here the system labels work materials for a Codipack customer. The ALtech ALline labelling line is suitable for labelling cylindrical, elliptical and rectangular packages.

C labeling salads

C-labelling is often used to label food such as salads and cakes. This is perfectly possible with the ALtech ALbelt of Codipack Group. At high speed.

C-labelling packaging cake

Labelling cakes in an automatic way. With C-labelling, which is widely used in the food sector.

C-labelled cake packaging

Here, the packages of cakes are automatically labelled. C-labelling is usually used for this. In this example, the systems from ALtech are used.

Wrap around labeling of jars

The jars of Wildiers' traditional jams, jellies & marmalades are labelled here. This system is fully automated and called ALline.

Wrap around labelling of vials

This labelling machine has been specially designed for labelling vials and boxes in the pharmaceutical industry.Laser

Coding on plates, crates and pallets

Here you can see various applications on wood, including laser systems and inkjet for permanent coding. Print & apply is also possible.

Lasering of cardboard boxes

The Macsa SPA CIP is at home in the logistics sector. This is the former and now improved KIP1080 version. Here you can see it at work with our customer TVH.

Lasering of soft drinks

At this soft drink giant, the codes are applied at extremely high speed. The laser systems are reliable and the process runs at very high speed.

Permanent code on rice packaging

On cardboard packaging of rice, we apply the necessary codes with a laser.

Laser plastic jars with mayonnaise

Laser is regularly used in the food sector. The codes applied are non-erasable and laser is also a cheap system to maintain. You do not need any consumables either.Small character inkjet

Print on top side of metal profiles

Avasco Industries specialises in the production of metal storage systems. Here, profiles are coded with a small character inkjet.

Coding the top of packaging

On the packaging of Godiva Chocolade, we encode the lot codes and tht codes. This is done at high speed with a small character inkjet.

Top coding of meat packaging

At Quality Meat Product, the plastic meat packaging is given a code on the top. This small character inkjet does this without contact.

Coding on narrow cables

At Caparis, the cables are printed with text and codes. This is done with a small character inkjet printer, the Jet3up from the brand Leibinger.

Coding of eggs

These eggs get a code. This small character inkjet is integrated within a Moba system.

Marking on cable with pigmented ink

Cables get a logo with a small character inkjet. This is done with pigmented ink. Readability is thus optimised.High resolution inkjet

Coding the top of PVC pipes

Here, a marking is applied to the top of PVC pipes. This application is often used in the construction sector.

Coding on plates, crates and pallets

Here you can see various applications on wood, including laser systems and inkjet for permanent coding. Print & apply is also possible.

Vinyl floor top coding

REA JET HR marking systems use newly developed inks to mark smooth surfaces cleanly, environmentally friendly and solvent-free.

Codes and markings on boxes

This high resolution printer prints the cardboard boxes at Klaasen & Co in Ravels. In this way, the chickens in the soup are given the correct details so that they are always traceable afterwards.

Printing on pallets with inkjet

The European Pallet Association (EPAL) has approved an inkjet system from Codipack for printing on pallets. Discover the Diagraph IJ4000.Inkjet HP

Codes on the side of cardboard boxes

In the logistics sector, it is important to be able to trace everything properly. Applying codes on packaging and boxes can be done efficiently with high resolution inkjet systems.

Printing codes on blisters

The codes on medication must be very clearly legible. Large volumes are produced at high speed with this inkjet HP.

High resolution inkjet

Various inks are available for this HP by Rea Jet. Even white pigmented to print on dark surfaces.

Marking around car tyres

A clear marking, around car tyres. This high resolution inkjet system from Rea Jet shows how it can be done..

Coding of plastic bags

Borealis produces large quantities. Speed is also important. Here, filled bags are coded at high speed with an inkjet HP.

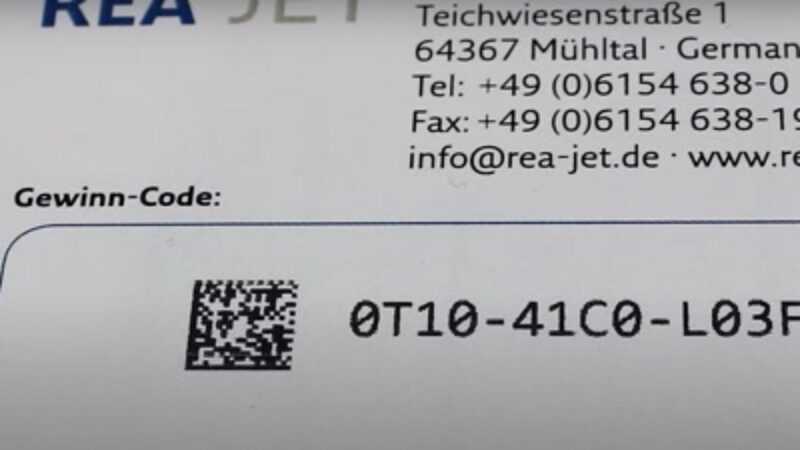

Unique promo codes on labels

These promotional codes are applied at very high speed to pre-printed labels. Each code is unique. Programming is done with NiceLabel software. The printing of the code itself is done with an inkjet HP.Inkjet DOD

Top coding patterns

For this textile manufacturer of curtains, the patterns are drawn with an inkjet. This makes it possible to work very precisely.

Wrap around coding of metal barrel

Codes are placed on these barrels. This is done with a Rea Jet DOD print head. While the barrels are rotating, the inkjet is 'sprayed' onto them.

Apply codes on side of concrete block

With the DOD 2.0 print heads we apply markings on concrete blocks at Holcim Belgium. They are from the brand Rea Jet that Codipack distributes.

Large markings on building materials pallets

In certain cases, inkjet is the best option for marking your pallets. As you can see here, on building materials.

Inkjet DOD 2.0

This inkjet from Rea Jet prints at high speed on absorbent and non-absorbent surfaces.

Marking on the side of concrete blocks

The DOD 2.0 inkjet print heads are used here to apply markings to large concrete blocks.Inkjet marking heads

Inkjet marking heads

Here you can see the marking heads of Rea Jet at work. Find out what they can do for your business.TTO printer

Codes on empty plastic packaging

Compo Expert produces fertilisers for professional users in the fruit and vegetable sector.

Codes on plastic packaging

This inline printer prints codes on food packaging. The lot number is an important identification in the food sector.

Codes on plastic bags

With this inline printer from Codipack, Friesland Campina applies text and codes to transparant plastic bags.

Labels on tin boxes

At our customer A&A Chocolaterie, the boxes are given a sleeve and a label is stuck at the bottom of the box. All ingredients and necessary markings and codes are listed on this.

Specifications on plastic bags

At this grain producer in Germany, the barcodes are meticulously printed on the empty bags. Then these bags are filled with grain.